✧ Description

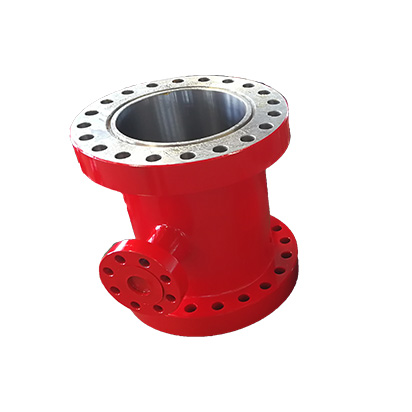

Drilling spool is designed to connect the BOP and wellhead, both side outlets of spool can be connected with valves or manifold to prevent blowout. All drilling spools are designed and manufactured as per API Spec 16A, conforming to NACE MR 0175 standard for anti- H2S. As per connection method, both Flanged spool and studded spool are available. Pressure-containing piece of equipment having end connections and outlets, used below or between drill-through equipment.

Drilling Spools are the parts which are often used in the oilfield when drilling, Drilling spools are designed to allow safe circulation of mud. Drilling spools usually have the same nominal end connections and the same nominal side outlet connections.

The drilling spool features a rugged construction, with precision-engineered connections that ensure a secure fit and reliable performance. It is compatible with a wide range of blowout preventers and other equipment, making it a versatile and indispensable tool for any drilling operation.

Safety is always a top priority in the oil and gas industry, and our drilling spool is designed with that in mind. It meets the highest industry standards for safety and reliability, giving you peace of mind knowing that your drilling operations are in good hands.

✧ Key Features

Flanged, studded, and hubbed ends available, in any combination.

Manufactured for any combination of size and pressure ratings.

Drilling and Diverter Spools designed to minimize length while allowing sufficient clearance for wrenches or clamps, unless otherwise specified by the customer.

Available for general service and sour service in compliance with any temperature rating and material requirements specified in API specification 6A.

Tap-end studs and nuts are normally provided with studded end connections.

✧ Specification

| Product Name | drilling spool |

| Working Pressure | 2000 ~10000psi |

| Working Medium | oil, natural gas, mud and gas containing H2S,CO2 |

| Working Temperature | -46°C~121°C(Class LU) |

| Material Class | AA, BB, CC, DD, EE, FF, HH |

| Specification level | PSL1-4 |

| Performance class | PR1 - PR2 |