✧ Description

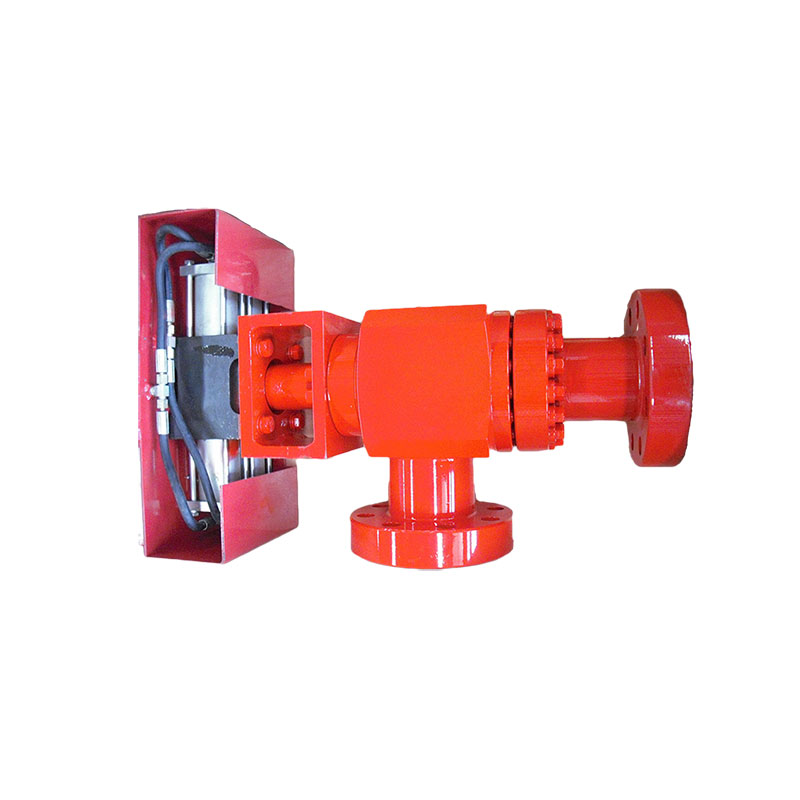

The plug and cage choke valve uses the plug as the controlling element and throttles the flow on the internal diameter of the ported cage. The ports in the cage are sized and arranged to give the most appropriate combination of control and flow capacity for each application.

A major consideration when sizing the choke is the ability to closely manage well startup while optimizing capacity toward the end of well life to maximize production.

The plug and cage design is highly optimized and incorporates the largest-possible flow area, making it ideal for high-capacity applications. Plug and cage chokes also are constructed with a solid tungsten carbide plug tip and inner cage for extended resistance to erosion. These valves may further be configured with a solid tungsten carbide wear sleeve in the outlet of the body to provide enhanced protection in sandy service.

Plug & cage chokes also are constructed with a solid tungsten carbide plug tip and inner cage for extended resistance to erosion. It may further be configured with a solid tungsten carbide wear sleeve in the outlet of the body to provide enhanced protection in sandy service.This trim also includes a thick metal outer cage to ensure maximum protection against solid impacts from debris in the flow.

✧ Feature

● Tungsten carbide pressure -controlling parts provide better erosion and corrosion resistance and longer service life than normal material.

● Fanged or thread type design as per client's request.

● Easy of filed service,maintenance and pressure controlling parts replacement.

● Stem seal design covers full range of pressures, temperatures, and fluid encountered in wellhead and manifold service.

✧ Specification

| Standard | API SPEC 6A |

| Nominal size | 2-1/16"~4-1/16" |

| Rated pressure | 2000PSI~15000PSI |

| Product specification level | PSL-1 ~ PSL-3 |

| Performance requirement | PR1~PR2 |

| Material level | AA~HH |

| Temperature level | K~U |