✧ Description

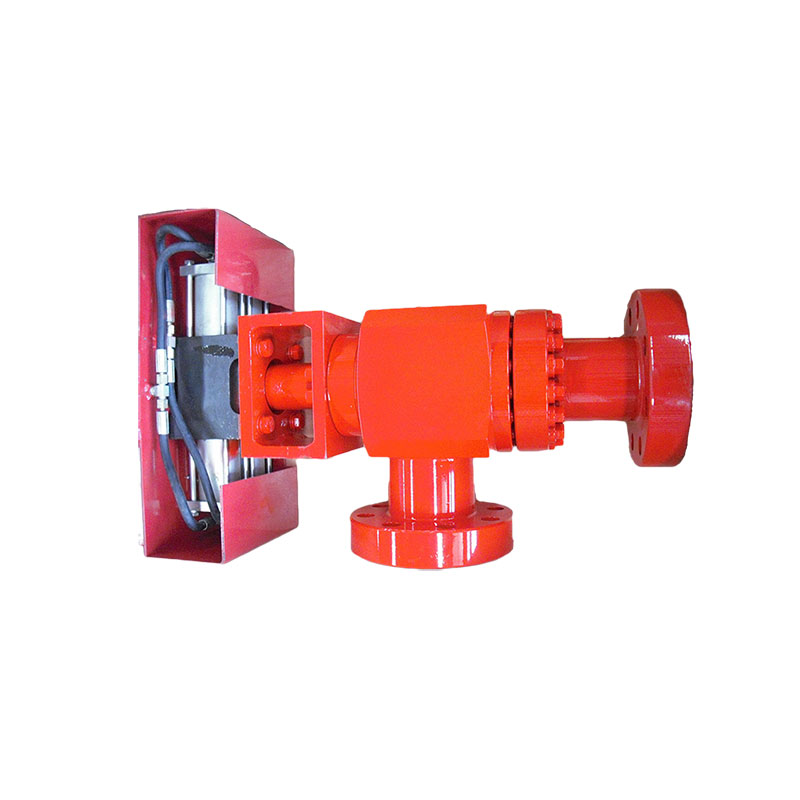

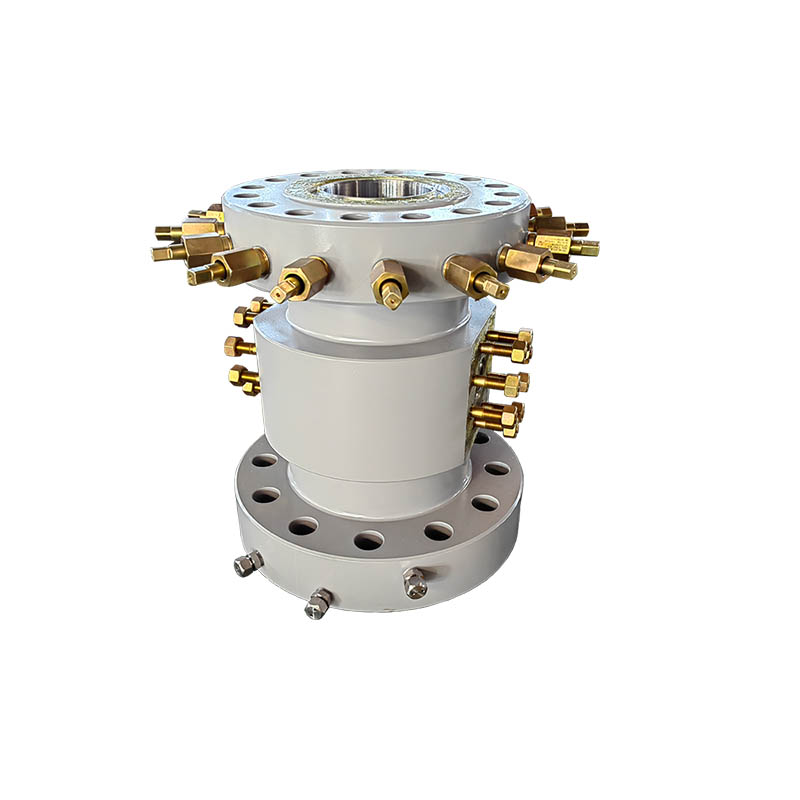

The Tubing Head is the uppermost spool in a wellhead assembly. It provides a means to support and seal a tubing string. The upper section has a straight type bowl and a 45 degree load shoulder to support and seal the tubing string by means of a tubing hanger. There is a full set of lock-screws to safely secure the tubing hanger in the head. The lower section houses a secondary seal to isolate the production casing string and provide a means to test the wellhead seals. Threaded or weld-on tubing heads attach directly to the production casing.

Allows for suspending the production tubing in the wellbore.

Provides a seal bore for the Tubing Hanger.

Incorporates Lock Down Screws to retain the Tubing Hanger and energize its seals in the seal bore.

Supports the blowout preventers (i.e. "BOP's") while drilling.

Provides outlets for fluid returns.

Provides a means to test the blowout preventers while drilling.

Has flanges on both the top and bottom of the assembly.

Has a seal area in the bottom flange for a secondary seal between the casing annulus and the flanged connection.

Utilize a test port in the bottom flange that allows for the secondary seal and the flanged connection to be pressure tested.

Our tubing heads are suitable for a variety of drilling applications, including onshore and offshore wells. It is compatible with various types of wellhead equipment and can be easily integrated into existing drilling rigs, making it a versatile and cost-effective solution for oil and gas industry operators.

We understand the importance of reliability and durability in drilling operations, which is why we are proud to offer tubing heads that meet the highest industry standards. Our tubing heads are rigorously tested and certified to ensure compliance with industry regulations and standards, giving operators confidence that our products will perform consistently and safely in the field.