✧ Description

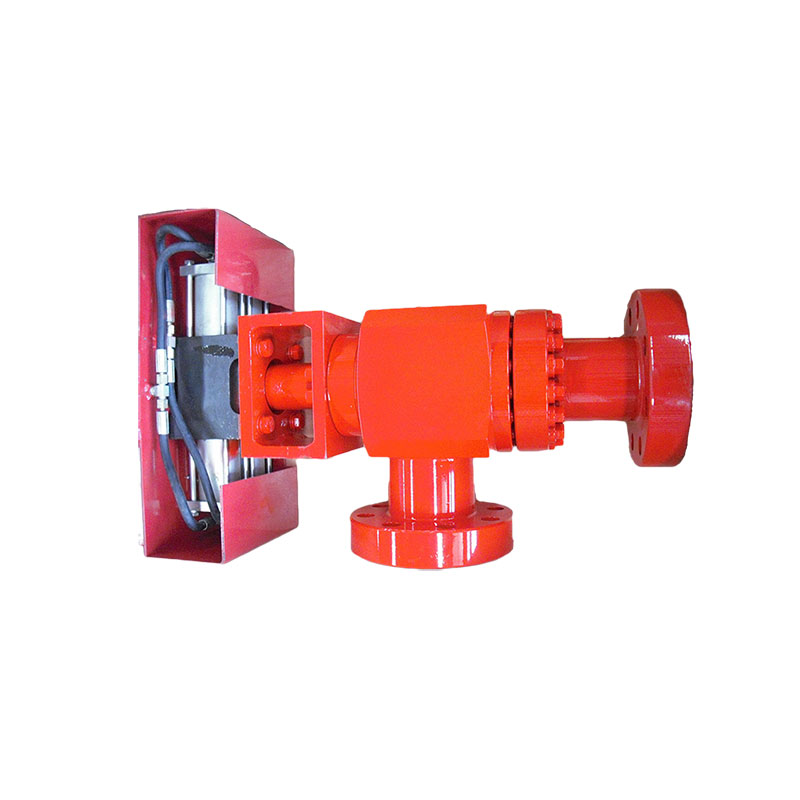

Swing check valves are a trusted choice for general-purpose use in both upstream and midstream applications, available in both forged or cast materials, and the design ensures total reliability for high pressure and high temperature services. The swinging action of the disc away from the seat allows forward flow and when the flow is stopped, the disc returns to the seat, preventing backflow.

Swing check valves are suitable for installations in lines where pigging operations are required for various maintenance services. The piggable design makes the swing check valve ideal for installation in riser pipelines and subsea applications. Convenience of operation and simple in-line maintenance are essential features of our design. Internal parts can be inspected and repaired without removing the valve off the pipeline even where space is restricted as in the top entry trunnion ball valve construction. The valve can be installed in both vertical and horizontal positions and offers unsurpassed quality and reliability– while the simple design minimizes maintenance costs.

One of the key features of our API6A Swing Check Valves is their robust construction. These valves are made from high-quality materials such as carbon steel, stainless steel, and alloy steel, ensuring they can withstand the harsh conditions often encountered in oil and gas operations. Additionally, the valves are designed for easy installation and maintenance, with a simple yet effective design that minimizes downtime and reduces the need for frequent servicing.

The design of our API6A Swing Check Valves incorporates a swing-type disc that allows for smooth and unobstructed flow of fluids. This design feature helps to prevent backflow and ensures that the valves provide reliable performance in both vertical and horizontal piping systems. The valves are also available in a range of sizes and pressure ratings to suit different application requirements.