✧ Description

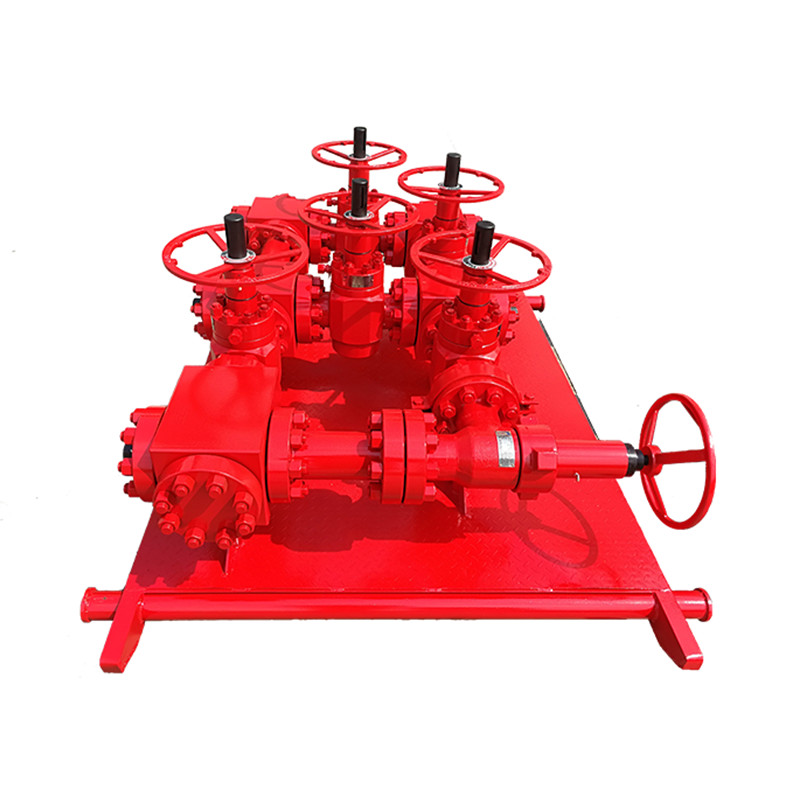

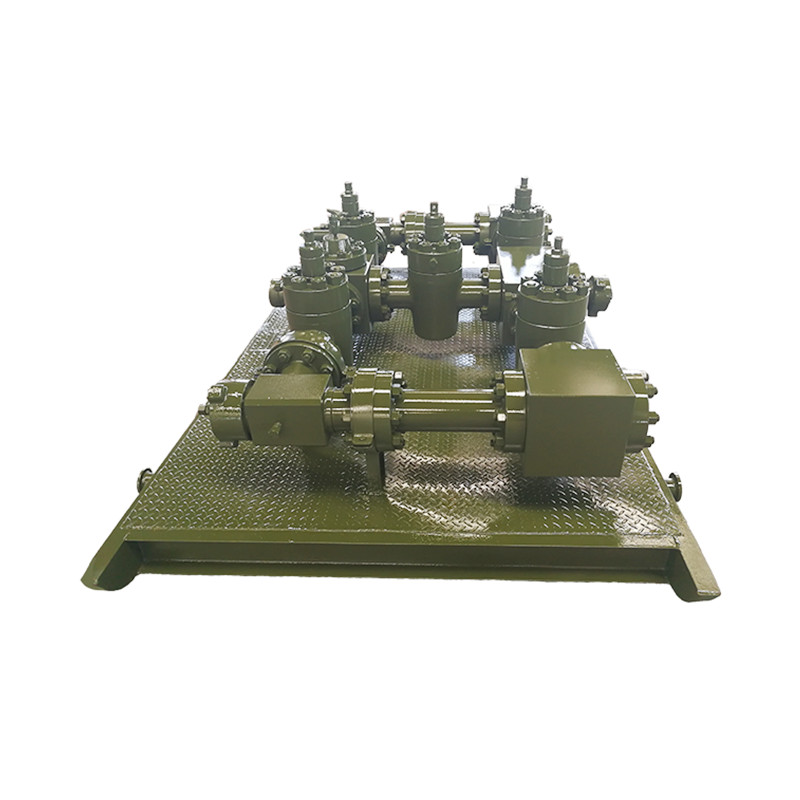

A choke manifold is a critical component in the oil and gas industry that helps control the flow of fluids during well drilling and production operations. The choke manifold consists of various components, including choke valves, gate valves, and pressure gauges. These components work together to provide precise control over the flow rate and pressure, ensuring the safety and efficiency of the drilling or production operation.

The primary purpose of a choke manifold is to regulate the flow rate and pressure of fluids within the well. It can be used to control the flow during well control situations such as kick control, blowout prevention, and well testing.

The choke manifold plays a crucial role in preventing excessive pressure buildup in the well, which can lead to equipment failure or even blowouts. By using the choke valves to restrict the flow, operators can effectively manage the well pressure and maintain safe operating conditions.

Our choke manifold is also available in different configurations to accommodate various wellbore conditions and operational requirements, providing versatility and flexibility for different drilling applications.Additionally, our choke manifold is designed to meet industry standards for safety and environmental regulations, providing a reliable and compliant solution for oil and gas drilling operations.

Overall, the choke manifold is an essential tool in the oil and gas industry, enabling operators to control and regulate the flow of fluids during drilling and production operations, ensuring safety and efficiency.

✧ Specification

| Standard | API Spec 16C |

| Nominal size | 2-4inch |

| Rate Pressure | 2000PSI to 15000PSI |

| Temperature level | LU |

| Production specification level | NACE MR 0175 |