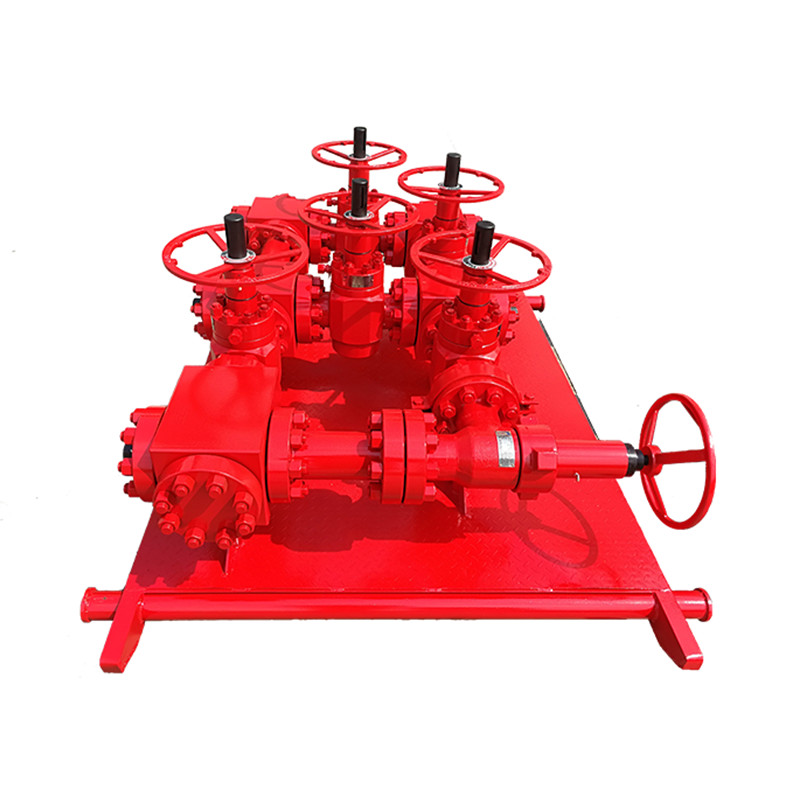

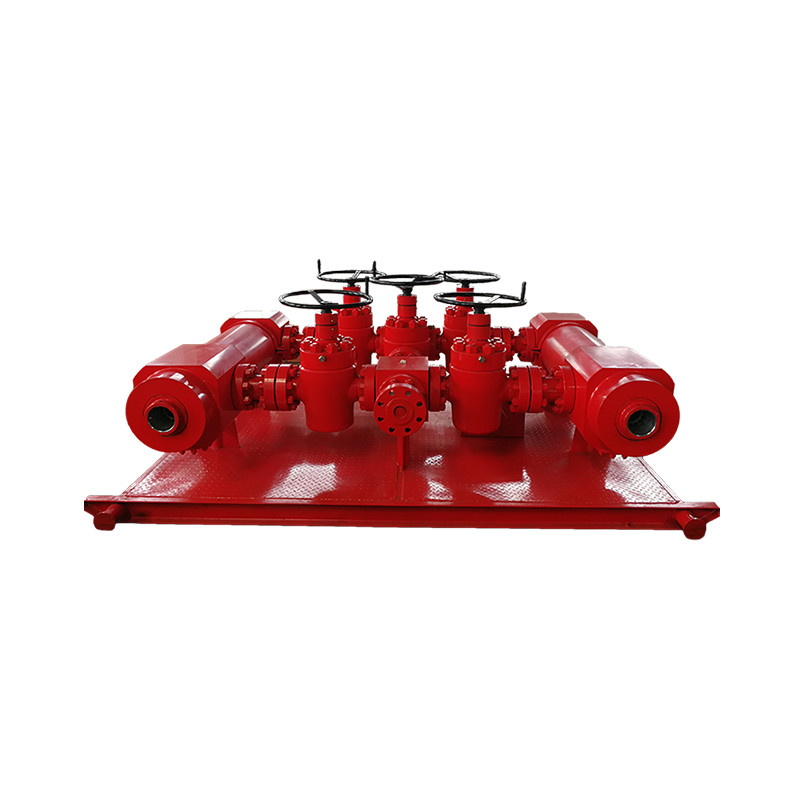

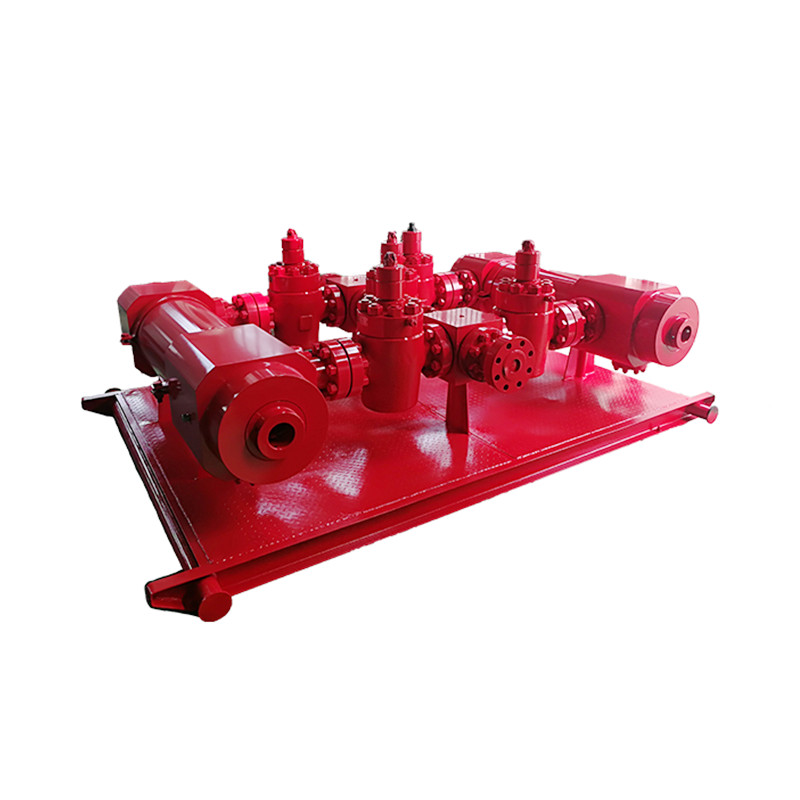

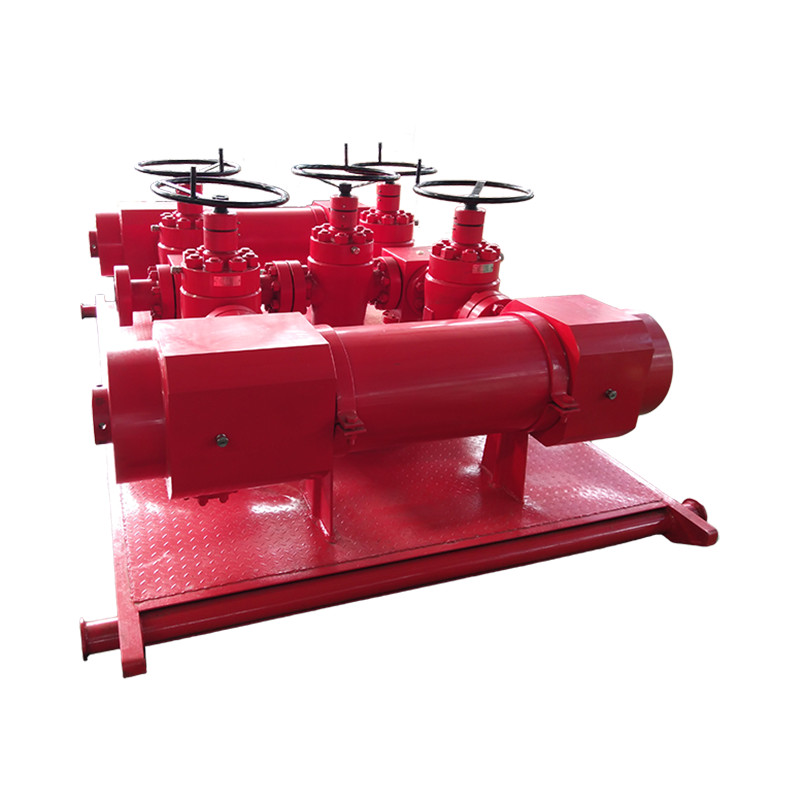

✧ Product Specifications

● Single barrel with bypass or dual barrel.

● 10,000- to 15,000-psi working pressure.

● Sweet or sour service rated.

● Plug-valve- or gate-valve-based design.

● Option for hydraulically controlled dumping.

A plug catcher is a device used in the oil and gas industry to manage debris during flowback and cleanup operations. It helps to filter out remnants of isolation plugs, fragments of casing, cement, and loose rock from the perforation area.

There are two common types of plug catchers:

1. Single barrel with bypass: This type of plug catcher features a single barrel and allows for continuous filtration during blowdown activities. It can handle working pressures ranging from 10,000 to 15,000 psi and is suitable for both sweet and sour service.

2. Dual barrel: This type of plug catcher also offers continuous filtration during blowdown activities. It consists of two barrels and is designed to handle similar working pressures. Like the single barrel type, it can be used for sweet or sour service.

Both types of plug catchers can be equipped with either plug-valve-based or gate-valve-based designs. Additionally, there is an option for hydraulically controlled dumping, which further enhances the functionality of the plug catcher.

Overall, plug catchers are essential tools in well cleanup processes as they help maintain a clear flow path by removing unwanted debris.