✧ Description

Flapper check valves include top-entry check valves and in-lineflapper check valves, which allow fluids to flow towards thewellbore and prevent flowing backwards. For dart check valvesthe flow will open the dart by overcoming the small spring force.

When the flow runs in opposite direction, the spring will pushthe dart against the seat retainer to prevent reverse flow.

We provides both standard and reverse-flow check valves. And we have also developed check valves for sour service inaccordance with NACE MRO175.

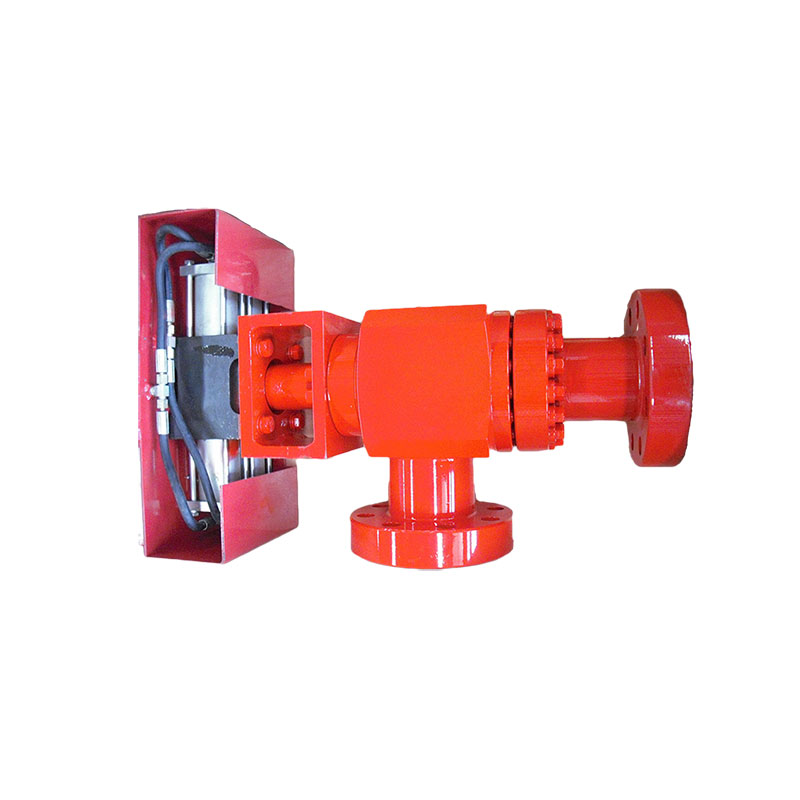

The API 6A flapper Check Valve is the ideal solution for controlling fluid flow in oil and gas production operations. Whether it's for new installations or retrofitting existing equipment, this check valve is a critical component for ensuring the safe and efficient operation of wellheads and Christmas trees in the oil and gas industry.

(1). Check valves are suitable for isolating completion fluid, high pressure processing and rig equipment repairing.

(2). The surface of valve internal baffle is covered with nitrile-butadiene rubber to extend life.

(3). The thread and the joint of ball face adopts American standard.

(4). The valve is casted by hard alloy steel and adopts union connection.

✧ Specification

| Material Class | AA-EE |

| Working Media | Crude oil and natural gas |

| Processing Standard | API 6A |

| Working Pressure | 3000~15000 psi |

| Processing Type | Forge |

| Performance Requirement | PR 1-2 |

| Product Specification Level | PSL 1-3 |

| Nominal Bore Diameter | 2"; 3" |

| Connection Type | Union, Box thread, Pin thread |

| Types | Flapper, Dart |