✧ Description

The core function of a blowout preventer is to act as a critical wellbore seal, ensuring that no unwanted fluids escape the well. With its sturdy structure and advanced sealing mechanism, it can effectively cut off the flow of fluid, providing a fail-safe measure against blowouts. This basic feature alone sets our BOPs apart from traditional well control systems.

Our blowout preventers also provide seamless activation in the event of gas or liquid impact or influx. It is equipped with a state-of-the-art control system that enables operators to quickly shut down wells, stop flow and regain operational control. This rapid response capability can significantly reduce the risks associated with well control events, saving valuable time and resources.

Our blowout preventers use the latest materials and are designed to withstand extreme pressures, temperatures and harsh environments, ensuring reliability even in the most demanding conditions. Its intelligent monitoring system continuously collects and analyzes critical data, providing operators with real-time feedback and allowing proactive decision-making.

Additionally, our BOPs are rigorously tested to comply with the strictest industry standards and regulations. Its robust design and superior performance have been proven through extensive field trials, earning the trust and confidence of industry experts worldwide.

Our commitment to sustainability is also reflected in the energy efficiency and environmental awareness of our BOP. With optimized power consumption and minimal carbon footprint, it not only improves operational efficiency but also minimizes environmental impact.

BOPs are designed to withstand high pressure and extreme conditions, providing a crucial barrier of protection. They are an essential part of well control systems and are subject to strict regulations and regular maintenance to ensure their effectiveness.

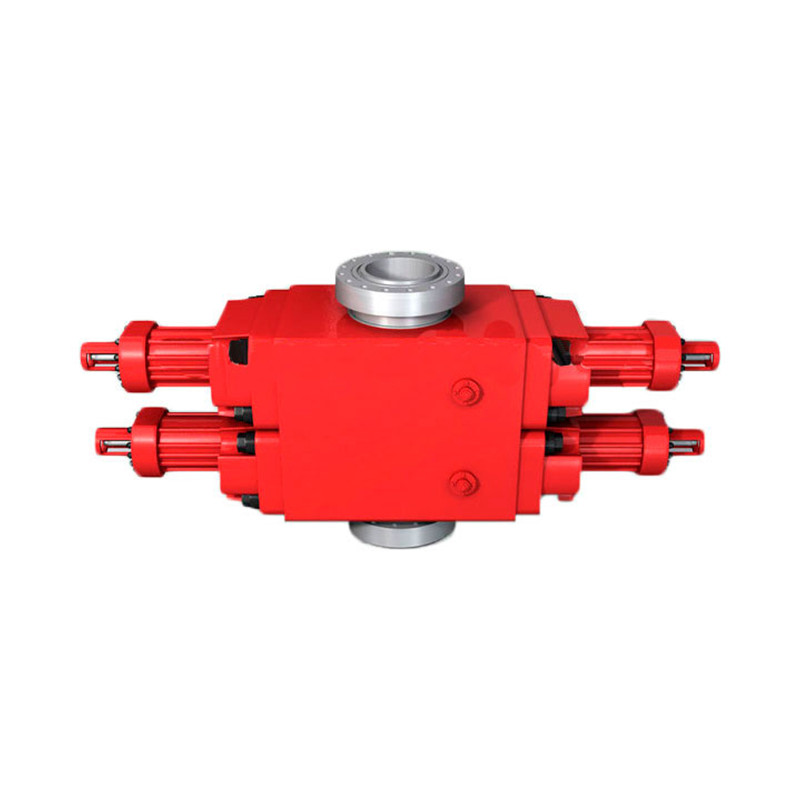

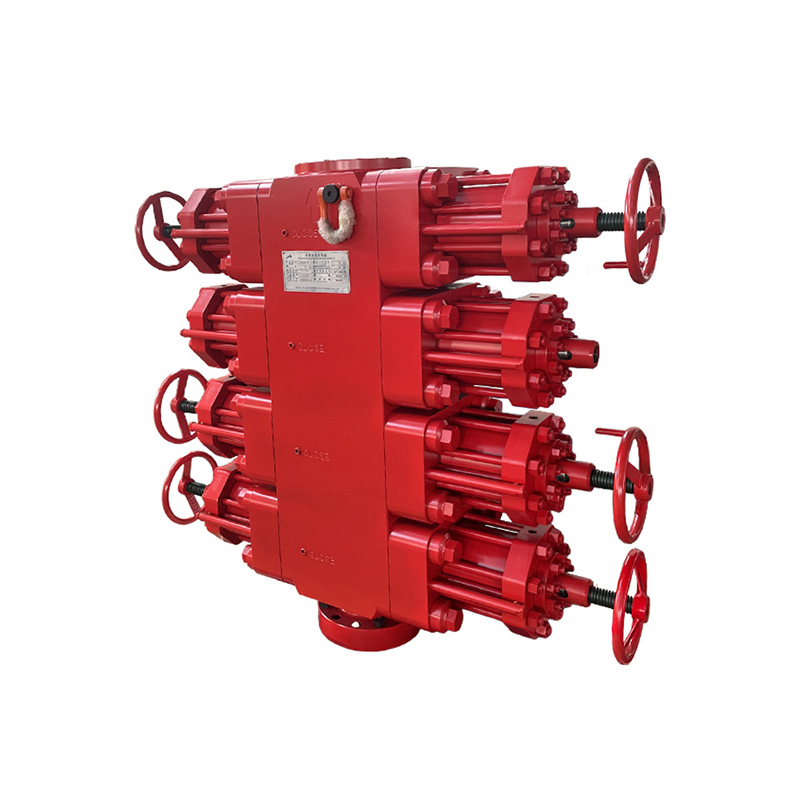

Type of BOP we can offer are: Annular BOP, Single ram BOP, Double ram BOP, Coiled tubing BOP, Rotary BOP, BOP control system.

✧ Specification

| Standard | API Spec 16A |

| Nominal size | 7-1/16" to 30" |

| Rate Pressure | 2000PSI to 15000PSI |

| Production specification level | NACE MR 0175 |